How to Measure a Machine Belt

Measuring for a lathe belt is easy. You need only measure for length and width:

Place your machine in running position and center your tension adjustment.

Many South Bend lathes have a lever below the headstock. This lever tensions the belt. When the lever is in the UP position, the belt is relaxed. When the lever is all the way DOWN, the belt is tight. Just inside the lathe’s door and to the right, there is an adjustment for tension. The adjuster consists of a threaded mechanism with a lock nut. Before measuring for a belt, this threaded adjuster should be backed down to make sure there is enough travel to tighten the new belt. Also, the lever should be in the DOWN position to measure around the pulleys.

The weight of the motor does not provide the tension. There are some machines that use motor weight to provide tension. The South Bend lathe is not one of those. On some machines that use motor weight for belt tension, bad things can happen. If the machine is put under severe load, the belt can slip or sometimes the motor will try to climb up the belt. The motor will bounce.

You may use a steel tape, dressmakers tape, or the plastic banding often used on shipping boxes to take an accurate measurement around your pulleys. The idea is to use something that will not stretch, but flexes smoothly around your pulleys. Sometimes it is handy to use a small piece of tape to secure one end of the measuring tape/banding to carefully go around your pulleys to meet with the taped end.

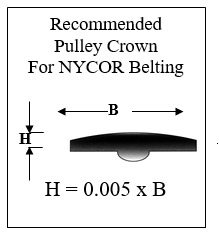

This will give you a length reading with good travel in both directions; the belt will not be too long or too short. For lathes, we need only your length and width measurements from your pulleys. (The belt should be a little narrower than the pulley).

Please do not ask us to tell you your measurement. We cannot see your machine, and we do not know the history of any changes made. While we are alert to a reading that does not seem quite right, it is still up to you to take the measurement as we ask. *Do not measure from an old or existing belt. If you follow our instructions, your belt will fit perfectly.

Cautionary note:

If you elect to use a 50’ or 100’ steel tape, do not bend the hook or triangle backwards when you measure around your pulleys! The hook is there to aid contractors who use a nail to hook the tape on so the measurement goes from that point forward. If you fold it back while taking your measurement, you will be off by as much as 3/4”.

Why We Ask You Not to Measure From an Old Machine Belt

When you measure a belt laid out on the floor, you are measuring the belt’s neutral layer. This measurement will be too short by an amount approximately equal to the belt’s thickness x pi (3.14). If you can measure the inside circumference by putting the belt in a circle and putting the tape measure inside the circle, your measurement will be closer. However, measuring around your pulleys is the correct way, because that measures the working length of the belt.

Why We Ask You Not to Measure From an Old Machine Belt

For machines without tension adjustment we ask that you pull the measuring tape as snug as possible. We will make the belt a bit tighter so you can walk the belt on. This applies to leather belts that will stretch a little. Sometimes this will apply to other materials, and in which other factors play a part.

Questions we may ask you, and answers you should be prepared to give us either by phone or email:

1. The make of your machine

2. Length and width of the belt you want, and how you arrived at the measurements.

3. Diameter and width of the driving and driven pulley

4. Horse power

5. RPM

6. Does the machine have tension adjustment?

7. Do you have an idler or plan to use one?

8. Environment where the machine is used.

Answers and descriptions may accompany clear digital photo(s). Contact Us page.

Note: If your pulleys are out of alignment, worn, or dirty/oily, – it pretty much goes without saying, but please get that corrected before applying a new belt.